Please sign in to include your comment.

Figuring out the bearing capacity of the combined stacked raft foundation having a modified equivalent raft method.

Raft Foundation

It’s suggested for an additional purposes:

Bearing capacity of soil is low,

it’s employed for large loads.

Kinds of foundations

shallow deep

supervisor: Dr Grzegorz Kacprzak

sincere thanks to: Dr Mirosaw Bukowski

Figuring out the bearing capacity of the combined stacked raft foundation having a modified equivalent raft method.

by – Tomasz Daktera

footings

raft

piles

diaphragm walls

ground reinforcement methods

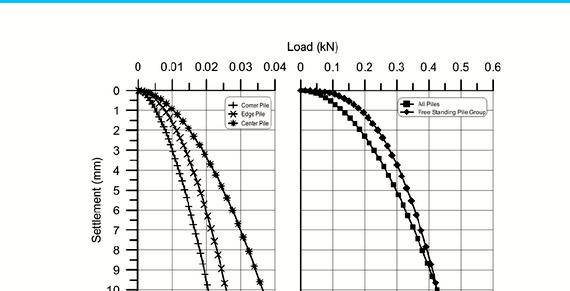

1. skin friction resistance

2. finish bearing resistance

Stresses in piles will always be adopted by settlements.

Clearly – the greater load – the bigger settlement.

Advantages:

It takes little excavation,

economic because of mixture of foundation and floor slab

Foundations.

Bearing capacity of piles and pile foundations – PN-83

Capacity of piles are calculated for settlements for example s=.1D

D- diameter from the pile.

General layout

intro

description of deep foundations

couple of words about piles

couple of words about raft foundations

the concept behind the CPRF

CPRF – the start

Polish code assumptions when calculating a pile group

My thesis – steps to make these calculations more exact

My assumptions

My calculations and results

Exactly what do I have left

future?

strip footing

pad footing

raft foundation

DSM posts

Stacked foundation

moored diaphragm wall

Spreads the load from the building on the large place to lessen the bearing pressures around the soil.

Resistance forces functioning on piles

The concept behind the CPRF

Stresses in piles will always be adopted by settlements.

Clearly – the greater load – the bigger settlement.

Capacity of piles are calculated for settlements for example s=.1D

D- diameter from the pile.

Overlapping Zones of Influence inside a Frictional Pile Group

Much deeper Zone of Influence for Finish-Bearing Pile Group compared to just one Pile

piles

raft

CPRF

ALL piles are made with similar assumptions:

same m1 coefficient for the entire pile group

results

same period of all piles

in

OPTIMIZATION?

Assumption I’ve designed for my optimization:

The earth beneath the raft displaces through the same amount because the raft.

cell

Due to the arching

The friction around the shafts isn’t activated overall perimeter.

Admissible bearing capacity from the interior pile:

(just like in PN-83)

Admissible bearing capacity from the corner pile:

Thesis:

May, 2014

key phrase:

interaction!

Admissible bearing capacity from the edge pile:

Le bearing capacity from the whole pile group:

amount of the bearing capacities of every pile as well as the earth found in the cell locked among the piles.

evaluating my leads to that relating to the EC7.

R

d

– calculated bearing capacity using the equivalent raft method.

1,3- partial factor for model and interaction incertitude

1,1 – partial factor in regards to the bearing capacity of the bottom of the friction around the shaft.

Introduction

COST ANALYSIS

SOIL

FOUNDATION

right TECHNOLOGY

under estimate

over estimate

collapse?

lose the tender?

cohesive

non-cohesive

high/low level

thickness of layers

Introduction

theory

of elasticity

comparison happen to be done

plastic

consolidation

settlements

DSM

changes

Ground Reinforcement methods

Jet Grouting

Stacked foundations

low bearing capacity of soil

non accessibility to proper bearing stratum at shallow depths.

heavy loads – not economical or achievable for any other kind of foundation.

Adopted generally within the following situations:

Various kinds of piles

Pile installation is as essential as design.

we’ve 2 ways of installation:

by driving

by boring

reference:

-driven pre-cast pile

-driven cast-in-situ pile

-bored pre-cast pile

-bored cast-in-situ

Ways of pile driving:

– shedding weight

– vibration

– explosion

generally with reinforcement

Advantages versus. disadvantages

could be inspected for quality

not prone to necking

are affected unseen domage

cohesive soil – impossible!

Driven pre cast piles:

Driven cast in-situ piles:

enlarged base possible

length may be easily adjusted

no inspection possible

noise and vibration

Bored and cast in-situ piles:

very lengthy depths

large diameter

concrete can’t be inspected

can’t be extended above walk out

Malbork – black oak piles (1278)

Venice – carefully spaced wooden piles (726)

The rafts stiffness is sufficient to visualize that piles are now being loaded with similar pressure.

An arching is produced due to the compression forces within the cell.

Silo method – Jenssen

2016 Prezi Corporation. Terms

Radha venkatachalam phd thesis proposal

Radha venkatachalam phd thesis proposal Communication design thesis project proposal sample

Communication design thesis project proposal sample Human resource management topics for thesis proposal

Human resource management topics for thesis proposal Thesis proposal presentation ppt sample

Thesis proposal presentation ppt sample Dahon ng pagpapatibay sa thesis proposal

Dahon ng pagpapatibay sa thesis proposal