Our Guarantees Our Quality Standards Our Fair Use Policy

What Makes UK Essays Different?

- We have a verifiable trading history as a UK registered company (details at the bottom of every page).

- Our Nottingham offices are open to the public where you can meet our team of over 40 full-time staff.

- UK Essays partner with Feefo.com to publish verified customer testimonials – both good and bad!

Ask an Expert FREE

Ask an Expert Index Ask a Question Paid Services

About Our Ask an Expert Service

Our totally free “Ask an Expert” Service allows users to get an answer of up to 300 words to any academic question.

- Questions typically answered within 24 hours.

- All answers are researched and written by fully qualified academics in the question’s subject area.

- Our service is completely confidential, only the answer is published – we never publish your personal details.

- Each professional answer comes with appropriate references.

About Us

More About Us

Published: 23, March 2015

CHAPTER 2

The first bridges were made by nature itself – as simple as a log fallen across a stream. The first bridges made by humans were probably spans of wooden logs or planks and eventually stones, using a simple support and crossbeam arrangement. Some early Americans used trees or bamboo poles to cross small caverns or wells to get from one place to another.

Figure 2.1 the The three Span Concrete claghorn bridge over blacklick creek

Some of the earliest surviving bridges date from around the second Century BC. Typically, they were stone arches, a form that dominated bridge construction until the arrival of wrought iron and steel in the early 18th Century and, 150 years later, concrete.

Most bridges were built by the church and two Renaissance stone bridges can still be seen in Paris – the Pont Notre Dame (1305) and the Pont Neuf (1606). It was in the 18th Century that bridge design began to develop into a science, led by an engineering school founded in Paris. Its director, Jean Perronet, perfected the masonry arch, with its low sweeping curve and slender piers. Soon afterwards, attention switched to England where the invention of the steam locomotive called for stronger bridges. In 1794, iron was first used for the chain cables of a suspension bridge over the River Tees and 1779 saw the first all-iron bridge over the Severn at Coalbrookdale. This arch bridge, spanning 100ft, is still in service.

Professional

Get your grade

or your money back

using our Essay Writing Service!

Essay Writing Service

Just when the masonry arch bridge was reaching its peak around the beginning of the 20th Century, reinforced concrete arrived on the scene. Since then, it has become the major construction material for bridges as it has for most structural and civil engineering applications, with its intrinsic versatility, design flexibility and, above all, natural durability. Although several British engineers had been using concrete early in the 19th Century, its use in British bridges did not develop until the latter half of the 20th Century. It is estimated that at least 75% of the Highways Agency concrete bridge stock has been built since 1960.

The earliest known example of a mass concrete bridge in the UK, using lime concrete, was on the District Line, near Cromwell Road, West London, designed by Thomas Marr Johnson for Sir John Fowler and built c.1865.

Other British engineers began to use plain concrete for bridge superstructures, notably Philip Brannan, who erected a three-span concrete arch, including a 50ft middle span, at Seaton in Devon in 1877. The use of reinforced concrete probably started with the Homersfield Bridge over the River Waveney on the Norfolk/Suffolk border in 1870, when iron was embedded in concrete, but it was not until the first decade of the 20th Century that reinforcement, as we know it today, was introduced. This was due almost entirely to L.G. Mouchel, the UK agents for the Hennebique system. The first project in the UK was an 18ft span bridge at Chewton Glen in Hampshire in 1902, followed two years later by a 40ft span beam and slab bridge at Sutton Drain in Hull.

The three bridges circa 1928, the Royal Tweed Bridge is almost ready for opening (middle)

By 1930 there were about 2000 reinforced concrete bridges in UK and notable designers such as Sir Owen Williams emerged between the two World Wars e.g. Montrose (1930). Other major bridges of this period were the Royal Tweed Bridge, Berwick (Mouchel); Chiswick and Twickenham River Thames Bridges (Considere); King George V Bridge, Glasgow and, possibly the best of the period, Waterloo Bridge, London. The outstanding feature of concrete bridges both during and after the Second World War was the advent of prestressed concrete, used to rebuild the many bridges that had been destroyed, especially on the Continent.

By 1950, bridges by Freyssinet and Magnel had been built, using precast segments joined by concrete or mortar; Finsterwalder had constructed the first in-situ box girder bridge using cantilever construction and in the 1960s, the first incrementally launched bridge was built in Germany. Reinforced concrete was still being used in the 1950s for larger bridges, especially arches, notably Lune Bridge carrying the M6, but by the end of the 1960s, prestressed concrete had largely superseded reinforced concrete with box girders being the dominant structural form.

Comprehensive

Plagiarism-free

Always on Time

Marked to Standard

Expansion of the motorway network demanded large numbers of concrete bridges, a functional and cost-effective solution to society’s needs. The main emphasis on bridge design became economy and durability rather than style. This inspired any number of developments and construction techniques, mainly involving precast segmental. The durability of concrete has also been recognised by its significant use on major estuarial crossings. Design and construction techniques continue to evolve to satisfy the increasing demands of the UK transport network e.g. integral bridges.

Hangzhou Bay Bridge (China): World’s Longest Trans-Oceanic Bridge

2.2 Loads on bridges

2.3 Type of bridges

There are six main types of bridges: beam bridges, cantilever bridges, arch bridges, suspension bridges, cable-stayed bridges and truss bridges.

Beam bridges are horizontal beams supported at each end by piers. The earliest beam bridges were simple logs that sat across streams and similar simple structures. In modern times, beam bridges are large box steel girder bridges. Weight on top of the beam pushes straight down on the piers at either end of the bridge

Cantilever bridges are built using cantilevers-horizontal beams that are supported on only one end. Most cantilever bridges use two cantilever arms extending from opposite sides of the obstacle to be crossed, meeting at the centre

Arch bridges are arch-shaped and have abutments at each end. The earliest known arch bridges were built by the Greeks and include the Arkadiko Bridge. The weight of the bridge is thrust into the abutments at either side

Suspension bridges are suspended from cables. The earliest suspension bridges were made of ropes or vines covered with pieces of bamboo. In modern bridges, the cables hang from towers that are attached to caissons or cofferdams. The caissons or cofferdams are implanted deep into the floor of a lake or river

Like suspension bridges, cable-stayed bridges are held up by cables. However, in a cable-stayed bridge, less cable is required and the towers holding the cables are proportionately shorter

Truss bridges are composed of connected elements. They have a solid deck and a lattice of pin-jointed or gusset-joined girders for the sides. Early truss bridges were made of wood, and later of wood with iron tensile rods, but modern truss bridges are made completely of metals such as wrought iron and steel or sometimes of reinforced concrete.

2.4 General description of a bridge type

The four main factors are used in describing a bridge. By combining these terms one may give a general description of most bridge types.

span (simple, continuous, cantilever),

placement of the travel surface in relation to the structure (deck, pony, through),

Material (stone, concrete, metal, etc.),

Form (beam, arch, truss, etc.).

2.4.1 Span

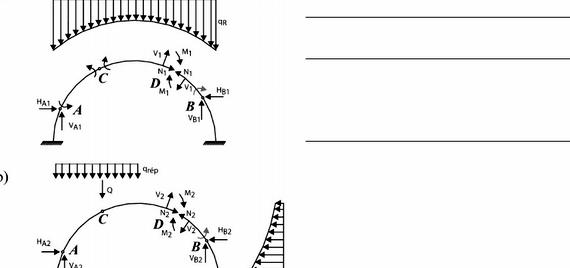

The three basic types of spans are shown below. Any of these spans may be constructed using beams, girders or trusses. Arch bridges are either simple or continuous (hinged). A cantilever bridge may also include a suspended span.

2.4.2 Placement

In a Deck configuration, traffic travels on top of the main structure; in a Pony configuration, traffic travels between parallel superstructures which are not cross-braced at the top; in a Through configuration, traffic travels through the superstructure (usually a truss) which is cross-braced above and below the traffic.

2.4.3 Material

2.4.3.1 Reinforced and Prestressed Concrete

Concrete is an all-round construction material. Almost every building contains some concrete. Concrete is poured into forms as a stiff but workable mix, and it can be given any shape; this is an advantage and a danger. The construction of good durable concrete requires special know-how – which the bridge engineer is assumed to have. Good concrete attains high compressive strength and resistance against most natural attacks though not against de-icing saltwater, or CO2 and SO2 in polluted air.

The steel bars only really come into play after the concrete cracks under tensile stresses. If the reinforcing bars are correctly designed and placed, then these cracks remain as fine hair cracks and are harmless. A second method of resisting tensile forces in concrete structures is by prestressing. Prestressed concrete revolutionized the design and construction of bridges in the fifties. With prestressed concrete, beams could be made more slender and span considerably greater distances than with reinforced concrete. Prestressed concrete – if correctly designed – also has a high fatigue strength under the heaviest traffic loads. Prestressed concrete bridges soon became much cheaper than steel bridges, and they need almost no maintenance – again assuming that they are well designed and constructed and not exposed to de-icing salt. So as from the fifties prestressed concrete came well to the fore in the design of bridges.

This Essay is

This essay has been submitted by a student. This is not an example of the work written by our professional essay writers.

Examples of our work

All types of structures can be built with reinforced and prestressed concrete: In bridge building, concrete beams and arches predominate. The shaping of concrete is usually governed by the wish to use formwork which is simple to make. Plain surfaces, parallel edges and constant thickness are preferred. This gives a stiff appearance to concrete bridges, and avoiding this is one task of good aesthetic design.

There is one great disadvantage to concrete as it emerges from the forms: the inexpressive, dull grey colour of the cement skin. The surfaces frequently show stains, irregular streaks from placing the concrete in varying layers, and pores or even cavities from deficient compaction, which ire then patched more or less successfully. These deficiencies have lead to a widespread aversion to concrete, As well as to efforts for improvement. Some of the methods used to achieve a good concrete finish in buildings, like profiles and patterns on the formwork, ribs or accentuated timber veins etc are not generally suitable for bridges.

The best effect is obtained by bush hammering as was usual between 1934 and 1945 for the bridges of the German autobahn system. The concrete coating of the rein- forcement is increased by 10 to 15 mm, so that a thin layer together with the cement skin can be taken off by fine or coarse bush hammering. The aggregate is then exposed with its structure and colour.

2.4.3.2 New materials

Concrete design specifications have in the past focused primarily on the compressive strength. Concrete is slowly moving toward an engineered material whose direct performance can be altered by the designer. Material properties such as permeability, ductility, freeze-thaw resistance, durability, abrasion resistance, reactivity, and strength will be specified. The HPC (high performance concrete) initiative has gone a long way in promoting these specifications, but much more can be done. Additives, such a fibers or chemicals, can significantly alter the basic properties of concrete. Other new materials, such as fiber-reinforced polymer composites, nonmetallic reinforcement (glass fiber-reinforced and carbon fiber-reinforced plastic, etc.), new metallic reinforcements, or high-strength steel reinforcement can also be used to enhance the performance of what is considered to be a traditional material. Higher strength reinforcement could be particularly useful when coupled with high-strength concrete. As our natural resources diminish, alternative aggregate sources (e.g. recycled aggregate) and further replacements of cementitious materials with recycled products are being examined. Highly reactive cements and reactive aggregates will be concerns of the past as new materials with long-term durability become commonplace. New materials will also find increasing demand in repair and retrofitting. As the bridge inventory continues to get older, increasing the usable life of structures will become critical. Some innovative materials, although not economical for complete bridges, will find their niche in retrofit and repair.

Figure Wrapping of carbon fibre sheet (a) pasting glue (b) wrapping the first layer

(c) bonding on the first layer

2.4.4 Decks

The most common type of concrete deck, by far, is the Cast-in-place (CIP). Their main advantage is the ability to provide a smooth riding surface by field-adjustment of the roadway profile during concrete placement. In recent years automation of concrete placement and finishing has made this system cost-effective. However, CIP slabs have disadvantages that include excessive differential shrinkage with the supporting beams and slow construction. Recent innovations in bridge decks have focused on improvement to current practice with CIP decks and development of alternative systems that are cost-competitive, fast to construct, and durable. Focus has been on developing mixes and curing methods that produce performance characteristics such as freeze-thaw resistance, high abrasion resistance, low stiffness, and low shrinkage, rather than high strength. Full-depth precast panels have the advantages of significant reduction of shrinkage effects and increased construction speed and have been used in states with high traffic volumes for deck replacement projects.

Several countries use stay-in-place (SIP) precast prestressed panels combined with CIP topping for new structures as well as for deck replacement. This system is cost-competitive with CIP decks. The SIP panels act as forms for the topping concrete and also as part of the structural depth of the deck. This system can significantly reduce construction time because field forming is only needed for the exterior girder overhangs. The SIP panel system suffers from reflective cracking, which commonly appears over the panel-to-panel joints. A modified SIP precast panel system has recently been developed in NCHRP Project 12-41.

2.5 section shapes

2.5.1 Column section shapes

The figure illustrates different possible section shape for reinforced concrete columns of bridge piers. The principal choice will be between circular and rectangular solid sections.

Sections A-A and B-B represent the common choice of columns with a circular distribution of longitudinal reinforcement contained within transverse reinforcement in the form of circular hoops or spirals. These sections are efficient, economical and easy to construct. The continuous curve of the transverse reinforcement results in excellent confinement of the core concrete and also provides effective constraint against buckling of the longitudinal flexural reinforcement. Section strength and displacement capacity are independent of direction of seismic response.

Section C-C the circular longitudinal reinforcements have been supplemented by additional reinforcement in the flare region. It is with monolithic superstructure designs and common to flare the top of the column to provide better support to the cap beam under eccentric live-load and also to improve aesthetics.

Section D-D has only peripheral hoop reinforcement, which is ineffective in confining the core concrete and in providing restraint against longitudinal bar buckling, and hence should never be used when ductile response is required of the pier. Providing adequate confinement using rectangular hoops, as is common in building columns.

Section E-E is possible for only comparatively small bridge columns.

Section F-F is common for large rectangular columns.semi- circular ends, or large chamfers are used to avoid excessive cover, with consequent potential spalling problems and to reduce sensitivity to diagonal attack. The spirals must overlap by a sufficient amount to ensure that shear strength is not compromised. When longitudinal response of a bridge with comparatively few spans is resisted principally by abutments, an elongated rectangular pier section shown in the fig. 26, Section G-G may be adopted. In the transverse direction, these sections act as structural walls, with high strength and stiffness, but in the longitudinal directions they have low stiffness, thus attracting little seismic force.

2.5.2 Superstructure Section shapes

Solid and voided slabs are appropriate for short span bridges, with spans below 15 m. the inverted T section is also used for short span bridges, with spans below 25 m. Typically an in situ deck is cast on the inverted T units, using shear connections between these units and situ slabs. The I beam is a common section for short span bridges. The double T section is used in the lower end of the medium-span range(25 to 35 m). However, this section is not suitable for bridges curved in the horizontal plane because of poor torsional characteristics.

Box girders have the advantage of having high stiffness and strength for minimum weight, and also high torsional characteristics. This last feature makes the sections suited for bridges curved in the horizontal plane.

Request Removal

If you are the original writer of this essay and no longer wish to have the essay published on the UK Essays website then please click on the link below to request removal:

More from UK Essays

Ponge le parti pris des choses dissertation writing

Ponge le parti pris des choses dissertation writing Les mots de liaison dans une dissertation writing

Les mots de liaison dans une dissertation writing Dissertation on motivation of employees pdf writer

Dissertation on motivation of employees pdf writer Writing a masters dissertation methodology sample

Writing a masters dissertation methodology sample Dissertation proposal presentation tips for trainers

Dissertation proposal presentation tips for trainers