advertisement

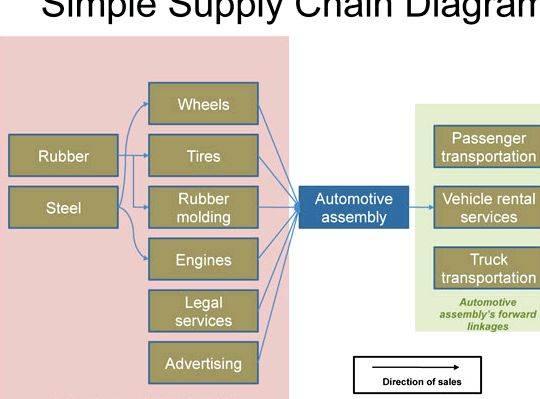

Any company that has a global supply chain should consider introducing its strategic left hand to its operational right hand. Strategic supply-chain planning that combines aspects of business-strategy formulation with aspects of tactical supply-chain planning can make each far more valuable to the planning effort than either would be alone. Strategic supply-chain planning is the Pegasus of strategy: It can soar, but it also needs to keep its feet on the ground. Although companies routinely weigh long-term supply-chain-related decisions in light of alternative sources of supply, new geographic markets or new products, various levels of management use different approaches, often in isolation. Senior managers make such decisions as part of formulating business strategy; supply-chain planners, as an extension of their tactical supply-chain planning.

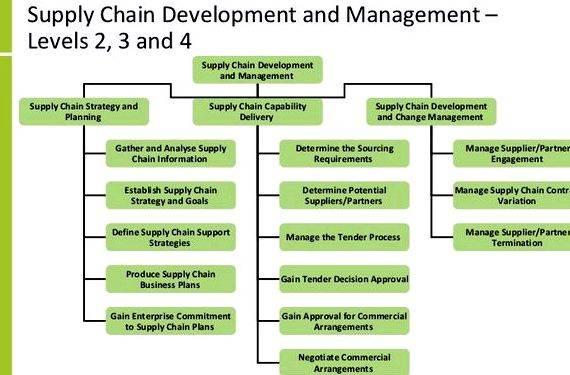

How should companies ensure that relevant supply-chain details inform the business-strategy formulation and that strategic direction and the supply chain are in alignment? They can do so through early communication between senior managers and supply-chain planners, which shortens strategy-implementation time while letting each group pursue its forte: senior managers formulating strategy to maximize shareholder value; supply-chain planners running optimization models to minimize total supply-chain costs.

One Company’s Story

Consider a strategic supply-chain planning exercise at a polyvinyl chloride (PVC) manufacturer that we’ll call Acme Vinyl Co. Acme’s North American revenues came from PVC for building (55%), packaging (15%), consumer goods (10%), the electronic industry (10%), the automotive industry (4%) and from non-PVC products (6%).

At the end of the 1990s about 4% of those revenues came from Asia. Acme had been seeing revenue growth for several years, mostly as a result of acquiring other PVC manufacturers.

With fragmented spare capacity around North America, a falling stock price and a need to rationalize the postacquisition supply chain, Acme’s leaders considered their options. Some favored consolidating manufacturing into one or two new mega-plants; others suggested closing existing plants or lines. Management chose to do a strategic supply-chain planning exercise to assist decision making.

The Planning Spectrum

Strategic supply-chain planning falls in the middle of a decision-making spectrum that has business-strategy formulation at one end and tactical supply-chain planning at the other. (See “Strategic Supply-Chain Planning and the Planning Spectrum.”) With a focus on fundamental changes in manufacturing and distribution capacity, it is long-term in scope and impact but can benefit from detailed optimization models and advanced planning-and-scheduling (APS) technology that is more often associated with medium- and short-term planning.

Business plan writing 101 course

Business plan writing 101 course Business plan writing 101 syllabus

Business plan writing 101 syllabus Best business plan writing apps

Best business plan writing apps Writing a business plan for an entertainment company

Writing a business plan for an entertainment company Step by step writing a business plan

Step by step writing a business plan