Our Guarantees Our Quality Standards Our Fair Use Policy

What Makes UK Essays Different?

- We have a verifiable trading history as a UK registered company (details at the bottom of every page).

- Our Nottingham offices are open to the public where you can meet our team of over 40 full-time staff.

- UK Essays partner with Feefo.com to publish verified customer testimonials – both good and bad!

Ask an Expert FREE

Ask an Expert Index Ask a Question Paid Services

About Our Ask an Expert Service

Our totally free “Ask an Expert” Service allows users to get an answer of up to 300 words to any academic question.

- Questions typically answered within 24 hours.

- All answers are researched and written by fully qualified academics in the question’s subject area.

- Our service is completely confidential, only the answer is published – we never publish your personal details.

- Each professional answer comes with appropriate references.

About Us

More About Us

Published: 23, March 2015

Abstract: We report the development and demonstration of a Long-Period Grating (LPG) based optical fiber sensor for determining the adulteration of coconut oil by palm oil. The fundamental principle of detection is the sensitive dependence of the resonance peaks of LPG on the changes of the refractive index of the environmental medium around the cladding surface of the grating. Refractive index sensing with LPGs employs light coupling between core and cladding modes in the grating section. The transmittance spectra of a long period grating element immersed in different mixtures of coconut oil and palm oil were recorded. Results show that resonance wavelengths and transmission intensities varied as a function of the adulteration level of coconut oil.

Detection limit of adulteration was found to be 2% for coconut oil-palm oil binary mixture.

Keywords: Long Period Grating, adulteration of coconut oil, optical fiber sensor.

1. Introduction

A food article is branded adulterated if any inferior or cheaper substance has substituted wholly or its part in a genuine food article, downgrading the quality of the product. Adulteration of edible oil – blending cheaper oil with premium oil – has always been profitable business for unscrupulous players. Higher the price of premium oil, greater is the propensity to adulterate it with low priced oil. Among the various edible oils, adulteration of coconut oil with palm oil is a common malpractice in South East Asian countries because of the low cost and easy availability of palm oil. Such adulteration results in many health hazards. The aroma of coconut oil will be quiet strong even after blending it with other oils. There will only be a slight change in the color of the oil which cannot be easily detected by the common man. By tactically exploiting these qualities of coconut oil, the practice of blending is very wide.

Professional

Get your grade

or your money back

using our Essay Writing Service!

Essay Writing Service

Different analytical techniques are employed in legitimacy testing of coconut oil. Among them are differential scanning calorimetry, fourier transform infrared spectroscopy, photopyroelectric detection etc.

These techniques have the disadvantage that they require considerable analytical skill. Due to increased public concern and legal requirements, the need for more reliable, rapid and less expensive monitoring and quality checking of coconut oil is growing continuously. Fiber-optic sensors offer great potential in this respect  due to their  intrinsic merits such as high sensitivity, small size, high performance etc.

Fiber gratings [1] are attractive fiber-optic devices that are being used in communication and sensing applications. Fiber gratings are prepared by creating a region of periodically varying refractive index within the fiber core and these gratings are often classified as Fiber Bragg Gratings (FBGs) [2] or Long-Period Gratings (LPGs) [3,4,5,6], according to grating period. LPGs typically have a grating period in the range 100 μm to 1 mm ,whereas FBGs have sub-micron period .Unlike FBG, LPG couples light from the fundamental core mode to other forward-propagating cladding modes, producing a series of attenuation bands in the fiber transmission spectrum that are centered at discrete wavelengths. The resonance wavelengths of the attenuation bands have been shown to be sensitive to the local environment experienced by the fiber, and LPGs have thus been proposed for use as sensors of strain [7], temperature [8] and bend curvature [9,10]. In addition, the LPG based sensors are also capable of responding to surrounding refractive index changes and are thus suitable for continuous real-time monitoring.

FBG becomes sensitive to external refractive index changes, when we allow access to the core’s evanescent field. The FBG RI sensor also lacks robustness because an FBG with a thin cladding breaks easily. Long-period gratings can be simple and robust surrounding medium refractive index sensors compared with FBGs, and so a number of studies on the RI sensitivity of LPGs have been conducted in various fields such as bio-chemical analysis and food and chemical industries[11,12,13,14,15].Besides offering all the advantages of optical fibers, LPGs also offer important key features like (i) wavelength coded information (ii) low back reflection, (iii) low insertion loss (iv) high coupling strength (v) relatively simple and cost effective fabrication (vi) easy interrogation (vii) core cladding coupling which makes LPGs extremely sensitive to variation in refractive index of material surrounding the cladding as the cladding field is strongly attenuated by it.

LPGs were first presented by Versangkar et al as optical filters in 1995 [4].Since then, LPGs have found many applications in optical communications such as gain equalizers[16], dispersion compensators[17], optical switches[18], components in wavelength division multiplexing (WDM) systems [19], band rejection filters[4] and mode converters [20]. The wide variety of applications makes it one of the stable and versatile technologies in optical field. The RI sensitivity of the LPGs has been exploited to form refractive index sensors, chemical concentration sensors and bio sensors.

Comprehensive

Plagiarism-free

Always on Time

Marked to Standard

Earlier we had reported a fiber optic intensity based evanescent wave sensor for the detection of adulterant traces in coconut oil using an unclad plastic fiber [21]. The main limitation of this evanescent wave sensor is that the cladding and small portion of the core has to be removed manually. This will reduce the mechanical stability of the fiber. In order to avoid this limitation, in this paper we are proposing a new LPG based sensor for the detection of adulteration in coconut oil which provides improved sensitivity range and robustness.

2. Theory of Operation

The basic principle of the LPG is to couple light from the fundamental guided mode (i.e. the LP01 mode present in the core) to other forward-propagating cladding modes (LP0m mode with m =2, 3, 4. ) in the fiber with periodical variation of the RI is shown in Fig.1.

Fig. 1. Mode coupling in a Long Period Grating.

Since the cladding generally has a large radius, it supports a large number of cladding modes. The cladding modes are lossy, and get quickly attenuated. As a result, the transmission spectrum of an LPG consists of a series of attenuation bands at discrete wavelengths, which satisfy the phase matching condition [4],

where is the resonance wavelength corresponding to coupling to the mth cladding mode, Λ is the grating period, is the effective index of the fundamental core mode (LP01), is the effective index of the mth-order cladding mode (LP0m). For a typical long period grating, more than one cladding mode can satisfy the phase matching condition at different wavelengths, and the guided mode will be coupled to all those cladding modes. The principle of operation mechanism of long-period grating sensors is based on the modulation of the effective indices of the core and cladding modes and/or the grating periodicity by the external perturbation. The study of the LPG’s attenuation bands has yielded many potential applications. The centre wavelengths of the attenuation bands are dependent on the composition of the fibre, and are influenced by environmental factors such as temperature, strain, refractive index of the material surrounding the fibre and bend radius. Thus it may be used for multi-parameter sensing applications.

The refractive index sensitivity of LPGs arises from the dependence of the phase matching condition upon the effective refractive index of the cladding modes. LPG is very useful as a surrounding medium refractive index sensor when the refractive index of the external medium changes. The change in ambient index changes the effective index of the cladding mode and will lead to wavelength shifts of the resonance dips in the LPG transmission spectrum. The RI sensitivity of LPGs has been exploited to form RI sensors, biosensors, liquid sensors and chemical concentration sensors by measuring the small shift in the resonant wavelength with a change in ambient refractive index [11,12, 13,14,15]. The effect of refractive index of the surrounding medium on the loss resonance wavelength is expressed by [6]:

where is the refractive index of the surrounding material. For each cladding mode, the term is distinct and hence an LPG is expected to have a strong dependence on the order of the coupled cladding mode. Greater ambient index sensitivity is exhibited in higher order cladding modes because these modes are less bound to the waveguide structure formed by the fiber itself [5,6,11]

4. Experimental Setup

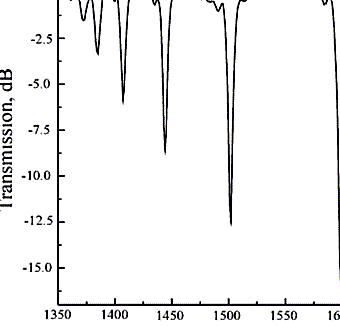

The experimental set-up (Fig.2) used to analyze the samples included a white light source ([Yokogawa] AQ 4305), a sensing LPG fiber, a glass cell and an optical spectrum analyzer ([Yokogawa] AQ 6319). We used an LPG with grating lengths of 21 mm and grating periods of 420 μm. The LPG was produced at CGCRI using a 248 nm KrF excimer laser source and used point-to-point writing method for fabrication. The hydrogen-loaded photosensitive fibre used has a cladding diameter of 125 micron and a numerical aperture of 0.14. The core and the cladding refractive indices are 1.463and 1.456, respectively. The fibre containing the LPG element was connected to the light source on one side and to the optical spectrum analyzer (OSA) on the other side to record the transmission spectrum. The spectra were recorded on the OSA in the wavelength range 1250-1700 nm. The LPG sensor head was fixed in a specially designed glass cell with provision for filling the sample and draining it out when desired.

This Essay is

This essay has been submitted by a student. This is not an example of the work written by our professional essay writers.

Examples of our work

Drastic changes in performance of the LPG had been noted when there were fluctuations in external characteristics like temperature, bending and strain. To avoid the effect of strain and bending a special glass cell holder was designed and the fiber was placed stretched and bonded with epoxy at both the end points of the cell such that the grating section was kept at the centre of the cell. For precise measurement, the experimental setup and sample solution temperature were maintained at 20.0 ±0.5 ÂC.

Fig. 2. Experimental setup.

The LPG’s RI response was measured by complete immersion of the fiber section containing the LPG in oil samples with different RIs. The transmission spectrum was recorded for sample mixtures of various concentrations. Sensor responded to RI changes as soon as new samples were introduced to the glass cell. But, to get a stabilized output, all readings were taken one minute after the LPG was immersed in the solution. The refractive indices of the samples, after draining out from the glass cell, were measured with an Abbe refractometer (model: RSR -1).

Â

At the end of each sample measurement, the grating was cleaned with isopropyl alcohol repeatedly, followed by drying properly, so that the original transmission spectrum of LPG was obtained. The changes in the refractive index of the surrounding medium were obtained by increasing the palm oil concentration in pure coconut oil samples. There was no protective coating in the grating section, so that the external RI could easily affect the effective refractive index of cladding modes. The refractive indices of pure coconut oil and palm oil were found to be 1.450 and 1.459 respectively.

5. Results Discussion

In the experiment, the LPG resonance wavelengths were monitored, while samples with different refractive indices were in contact with the grating. The highest order attenuation band was most sensitive to the surrounding refractive index changes. For the grating used in our studies the strongest attenuation peak, in air, is located at 1598 nm. Fig. 3 shows the grating response observed corresponding to this main attenuation dip with increasing concentration of palm oil in the mixture with coconut oil. The initial spectrum of the LPG in air is also shown for reference in Fig. 4

If the refractive index of the surrounding medium is lower than that of the cladding, the fiber supports bounded cladding modes that are maintained by total internal reflection at the surrounding cladding interface. In this case, the surrounding refractive index sensitivity arises from the evanescent wave interaction between the cladding modes and the external medium. This interaction will lead to a strong modification of the central wavelength of the attenuation bands. For RI values lower than that of the cladding, LPG sensitivity to increasing external index of refraction is evident as a blue shift in the central wavelength of the attenuation band in the grating’s transmission spectrum. The LPG exhibited a total blue shift of approximately 22 nm when the surrounding medium was gradually changed from pure coconut oil to 48 % adulterated coconut oil.

Fig. 3. Transmission spectra of the LPG surrounded by a medium having refractive index lower than that of cladding.

Fig. 4. Transmission spectrum of LPG with

Apart from the wavelength shift with the changes in refractive index of the external medium, LPG also produces a reduction in the peak intensity of the resonance band [5, 11]. It can also be observed that larger change in the resonant wavelength occurs when the refractive index of the external medium is close to the cladding refractive index [3,11,22]. The LPG is most sensitive to external refractive index changes in this region where index-matching occurs between the cladding and the surrounding medium [5,11].

When the value of the ambient refractive index matches with that of the cladding, the cladding layer acts as an infinitely extended medium and thus supports no discrete cladding modes. In this case, a broadband radiation mode coupling occurs with no distinct attenuation bands [23]. In precise, at an external RI equal to that of silica, rejection bands disappear, and the transmission spectrum gets flattened, as shown in Fig.5. We got a flat transmission spectrum when the adulteration level reached 52% corresponding to which the RI of the sample was close to that of the cladding.

Fig. 5. Transmission spectrum of LPG with

If the refractive index in the surrounding medium is higher than that of the cladding ( nsur nclad), the cladding mode propagates in accordance with Fresnel reflection from the cladding boundary, which is accompanied by the re-appearance of the grating peaks[24]. After the reappearance, there is no more spectral displacement, but the depth of each resonance peak increases as shown in Fig.6. The LPG exhibited a red-shift of approximately 16 nm from the main attenuation dip when the surrounding medium was changed to 60 % adulterated coconut oil. In short, for a surrounding refractive index higher than that of silica, the rejection bands reappear, but with high transmission and no wavelength response to external RI changes. Fig.7 shows the external RI-induced wavelength shift of the attenuation band corresponding to coupling to the sixth-order cladding mode.

Fig. 6. Transmission spectra of the LPG surrounded by a medium having refractive index higher than that of cladding.

Fig.7. Plot of the wavelength shift versus the RI of the oil mixture surrounding the LPG, for the attenuation band corresponding to 1598 nm

Fig.8 shows the sensitivity of the LPG when used as a sensor for various volume percentage of palm oil. It can be seen from the results that the sensor is useful to determine palm oil concentration even upto 2% by volume with a good linear sensitivity between 2 % and 48 %. This region is very useful because most of the adulteration and malpractices using palm oil are within this range. Repeatability has found to be poor below 2 %. A spectral shift of 22 nm was obtained in the refractive index range 1.450 to 1.456, which corresponds to an average resolution of 2.7 x 10-4 nm-1. The LPG sensor sensitivity was around 0.50 nm/vol% of palm oil in the measurement range.

Fig.8. Peak positions of the highest order resonance band in the LPG transmission spectra as a function of palm oil proportion.

6. Conclusions

In conclusion, we have designed and developed a simple fiber optic sensor for determining adulteration of coconut oil by palm oil. The advantages of this type of grating sensor are their simple fabrication, easy interrogation and it does not involve the use of solvents or toxic chemicals. The developed sensor is user-friendly, reusable and allows instantaneous determination of the percentage concentration of adulterant in a coconut oil sample without involving any chemical analysis. This sensor also showed very good repeatability. This work can be considered as a crucial step towards foodstuff security sleuthing applications.

We highly appreciate and acknowledge the support rendered by Fiber Optics Laboratories, Central Glass and Ceramics Research Institute,Kolkota, which contributed greatly to this work. The author TML is thankful to the Sree Chitra Thirunal College of Engineering, Trivandrum for their sponsorship. JL acknowledges the University Grants Commission, New Delhi, for financial assistance through RFSMS.

Request Removal

If you are the original writer of this essay and no longer wish to have the essay published on the UK Essays website then please click on the link below to request removal:

More from UK Essays

National history day 2016 thesis writing

National history day 2016 thesis writing Writing thesis abstracts in education

Writing thesis abstracts in education Architecture thesis proposals pdf creator

Architecture thesis proposals pdf creator Designer genes bill mckibben thesis writing

Designer genes bill mckibben thesis writing Pre-proposal for your masters thesis samples

Pre-proposal for your masters thesis samples