Our Guarantees Our Quality Standards Our Fair Use Policy

Why Is United kingdom Essays Different?

- There exists a verifiable buying and selling history like a United kingdom registered company (details at the end of each and every page).

- Our Nottingham offices are available to the general public where one can meet we well over 40 full-time staff.

- United kingdom Essays partner with Feefo.com to write verified customer testimonials – both negative and positive!

Ask a specialist FREE

Ask a specialist Index Ask an issue Compensated Services

About Our Ask a specialist Service

Our free of charge “Ask a specialistInch Service enables users to obtain an answer as high as 300 words to the academic question.

- Questions typically clarified within 24 hrs.

- All solutions are researched and compiled by properly accredited academics within the question’s area of interest.

- Our services are completely private, only the reply is printed – we never publish your individual details.

- Each professional answer includes appropriate references.

About Us

Much More About Us

Printed: 23, March 2015

Equal funnel angular pressing is definitely an emerging technique. It’s been accustomed to refine the grain size magnesium and it is alloys. Homogenized AZ31 alloy was processed through ECAP as much as two passes at specimen temperature of 3600C. AZ31 magnesium alloys were deformed from coarse grained into ultra-fine grained (UFG) material. The typical grain size the as-received AZ31 alloy was 22.5 µm also it was reduced to two.8 µm after processing through ECAP up to two passes. Mechanical qualities were experimentally calculated at 70 degrees. Generally, the effectiveness of the fabric decreased with improvement in percentage elongation through the growing quantity of passes. However, the hardness from the AZ31 alloy was elevated to 41.1% after two passes.

Key phrases: SPD, ECAP, AZ31, Grainsize, Microstructure.

Introduction

Severe plastic deformation (SPD) is really a material developing technique accustomed to refine the grains of numerous materials to nanometer scale [1,2]. Equal funnel angular pressing (ECAP) [3] is among the simplest and efficient procedure when compared with other approaches for example accumulative roll connecting (ARB) [4], ruthless torsion (HPT) [5], accumulative back extrusion (ABE) [6], accumulative torsion back (ATB) [7] to refine the grain size metals as well as their alloys. It’s been demonstrated by many people researchers that, the ECAP is a great refining method to develop different material qualities of metal and it is alloys like magnesium alloy [8], aluminium alloy [2] along with other materials for example Cu, Fe and Ti [9]. Extensive studies have been transported out by altering the die design and angles from 900 to 1500 as reported in [2, 3] to refine the grain size metallic and it is alloys. When compared to above materials reported within the literature magnesium and it is alloys have numerous advantages mainly when it comes to high strength to weight ratio and ductility [10,11,12,13]. This stuff are utilized in lots of applications like the structural material in automotive, aerospace, electronics and nuclear industries [14, 15]. Magnesium and it is alloys possess a hexagonal closed pack (HCP) structure as well as their slip product is poor at low temperatures [16] which is among the limitations additionally to a lot of benefits when compared with many other materials.

A lot of the job is not reported [9] concerning the comparison of numerous materials apart from aluminium with various die angles using ECAP process for that grain refinement. As a result it gave scope for that grain refinement of magnesium and it is alloys using ECAP technique at elevated temperatures to enhance mechanical qualities. The goal of the current jobs are to judge the grain size AZ31 wrought magnesium alloys using ECAP process. Microstructure examination is transported to verify the grain refinement of AZ31 alloy utilizing an optical microscope. Various kinds of experiments are carried out to determine the mechanical qualities of AZ31 alloy like tensile make sure hardness test. The different influencing factors on grain refinement is studied to know the mechanical behavior of AZ31 alloy.

Experimental Procedures

Professional

Get the grade

or a refund

using our Essay Writing Service!

Essay Writing Service

The schematic diagram of the ECAP for processing magnesium and it is alloys to refine grain dimensions are proven in Figure 1. This arrangement includes two equal channels intersecting in a particular position known as die position () and also the arc of curvature () subtended at the purpose of funnel intersection. In our work an ECAP die was created by having an position of 1200 and arc of curvature comparable to 300 to lessen the dead zone of fabric in addition to come with an equivalent strain close to .7 in every pass. An industrial AZ31 alloy folded sheet is machined into rods having a diameter of 16 mm along with a period of 80 mm. The fabric is homogenized for twenty-four hrs in a temperature of 4000 C to create all constituents right into a single phase before ECAP process. The experiment is carried out by using route BC procedure to refine the grain structure effectively so they can improve high-position grain limitations reported in [17,18,19]. Based on this process the sample is rotated at 900 around its longitudinal axis between your passes. The sample is pressed with the die funnel for 2 passes utilizing a plunger or ram to impose the big plastic strain with similar mix-sectional area by neglecting the finish effects. The sample is processed from 70 degrees towards the crystallization temperature from the material. The current jobs are transported out at 3600C for processing the AZ31 alloy. Further, the microstructure examination is transported to be aware of grain size alloy utilizing an optical microscope. The preparation of sample for testing involves mechanical polishing using different SiC papers and additionally, the colloidal Al2O3 and gemstone paste are utilized to obtain the mirror finishing. The mirror finished samples are subsequently etched by utilizing Picral (4.2g picric acidity, 10ml acetic acidity, 10ml H2O, 70ml ethanol) reagent [20]. The tensile make sure hardness test are conducted to judge the mechanical qualities from the AZ31 alloy. Figure 2 shows the tensile test specimen having a gauge length and diameter of 14.5 mm and 5 mm correspondingly prepared according to ASTM E-8 specifications and tested using Hounsfield Tensometer. Hardness test is completed using Vickers microhardness test rig by making use of a lot of 100g having a dwell time comparable to 13 s.

Results Discussion

Tensile Qualities

Comprehensive

Plagiarism-free

Always promptly

Marked to plain

The engineering stress versus engineering strain curves are plotted for AZ31 alloys as much as two passes as proven in Figure 3. The best tensile strength (UTS) and also the uniform percentage elongation are attracted from all of these curves and therefore are proven individually in Figure 4. The effectiveness of the as-received AZ31 Mg alloy has been discovered to become 232.88 MPa. Further, the UTS is improved upon to 242 MPa and 227 MPa after third and fourth pass correspondingly.

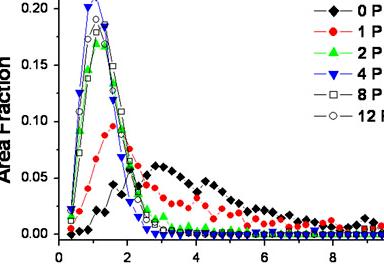

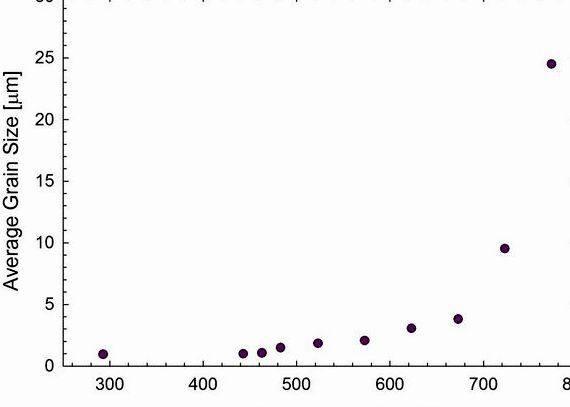

The yield strength from the AZ31 alloy is greatly elevated following the first pass when compared to as-received material but there’s a decrease following the second pass when compared to first pass. Nevertheless the yield strength from the materials are elevated after two passes over those of the unECAPed material. Thus, the yield strength is within good agreement using the hardness from the material and it has greatly elevated with rise in the amount of passes. Exactly the same trend is noted in AZ91 alloys [21]. The typical grain size the fabric is decreased because of the rise in the yield strength as observed from Figure 5 (a) -(d) and also the same continues to be expressed by Hall-Petch [1,9].

The ductility from the as-received materials are discovered to be 20.14%. Within the first pass the effectiveness of the fabric is elevated, although the ductility from the material continues to be decreased. It appears the material exhibits the strengthening effect because this was similarly observed by H K Kim et al. [22]. Following the second pass from the ECAP, the ductility is elevated by imposing the job hardening within the material. The job hardening from the material could be elevated by growing the amount of passes.

It might be figured the the mechanical qualities from the material may have been affected by the feel, grain refinement, the distribution of residual stresses, temperature, quantity of passes and die position from the ECAP process. The yield strength (YS), ultimate tensile strength (UTS) and percentage elongation for 2 passes shows up in Table 1 for much better knowledge of the variations included in this.

3.2 Microstructure Characterizations

Figures 5 (a)-(d) show the optical microstructures from the as-received. homogenized as well as for two passes of AZ31 alloys. The typical grain size as-received, homogenized, third and fourth pass of AZ31 alloy at 3600C are 22.5 µm, 18.9 µm, 11.2 µm and a pair of.8 µm correspondingly. More twins in large size around the grains are observed from Figure 5 (a). This can be due to the specimen being prepared from folded sheets because of existence of yield asymmetry. Additionally the shear deformation can happen in just one direction. It was discussed fully by S.M. Yin et al. [23]. AZ31 alloy has under five slip system planes because of hexagonal close packed (HCP) structure. Due to this reason the deformation can happen either twinning or dislocation slip based on ASTM [24]. The equiaxed large grains are noticed in homogenized AZ31 alloy at 4000C for 24hrs as proven in Figure 5(b). The grains are considerably refined from coarse to fine after shear deformation for any first pass at 3600C as proven in Figure 5 (c). Out of this it’s observed the fine grains are encircled by large coarse grains because it is a sign from the heterogeneous distribution of grains. It was described by Feng Kang et al. [25]. Figure 5 (d) shows the microstructure from the AZ31 alloy throughout the second pass at 3600C. It’s been observed the large grains are further decreased by growing the amount fraction of smaller sized grains. It represents the start of dynamic recrystallization [26] of fabric from second pass and it will further increase with rise in the amount of passes. Even the grain boundary angles rise in second pass when compared with as-received AZ31 alloy. Similar results happen to be observed by [27].

Hardness

The Vicker’s micro-hardness like a purpose of the amount of passes is highlighted in Figure 6. The typical hardnesses of as-received and homogenized AZ31 material are observed to become 51 HV and 53 HV correspondingly. They’re elevated by around 35% and 41.1% correspondingly after single and 2nd pass in a temperature of 3600C. It might be summarized the hardness from the AZ31 Mg alloy is considerably improved by growing the amount of passes. The hardness of AZ31 materials are 72 HV after two passes for that average grain size 2.8 µm. With this particular it’s summarized the hardness increases because of grain refinement because it increases with rise in the amount of passes which is perfectly shown by Face-Sang Chung et al. [16]. Further it might be figured the hardness could be improved by growing the amount of passes although the maximum hardness from the materials are elevated following the first pass at 3600C in our work.

Conclusions

Dissertation proposal defense presentation ppt download

Dissertation proposal defense presentation ppt download Phd thesis proposal sample ppt presentation

Phd thesis proposal sample ppt presentation Masters thesis proposal sociology degree

Masters thesis proposal sociology degree Acknowledgement sample phd thesis proposal

Acknowledgement sample phd thesis proposal Jonathan swift a modest proposal thesis

Jonathan swift a modest proposal thesis