Analysis from the Fundamental Growth Mechanisms in Pulsed Laser Deposition Synthesis of Nanostructured Materials

By WILLIAM THOMAS MOZET

Thursday, September 29, 2016 10:00 am Engineering Building B-223

Dissertation Director: Stephen D. Tse

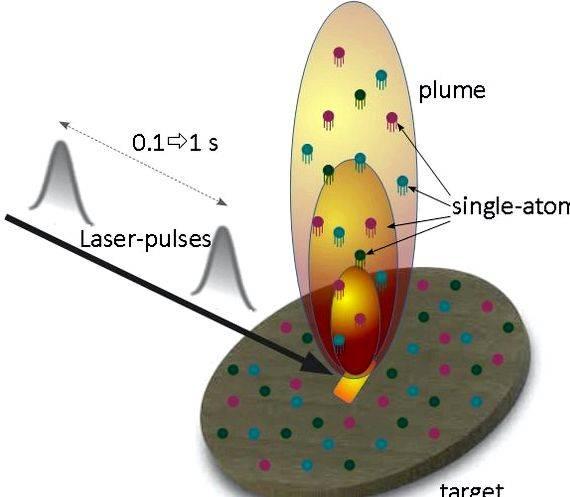

Research is conducted to higher understand growth mechanisms in pulsed laser deposition (PLD) synthesis of nanostructured materials, namely graphene and bismuth telluride (Bi2Te3). For graphene, because the substrate temperature increases, an order from the film increases, from an amorphous carbon film to nanocrystalline graphite and couple of-layer graphene (FLG). Using a high energy laser, the type and size of ablated species could be controlled to produce films with smaller sized nanocrystalline domains. PLD enables the thickness from the films to become directly controlled through the deposition duration. Films could be grown on arbitrary substrates, unlike other methods which utilize surface chemistry. Substrate morphology may also affect the samples, with greater surface roughness resulting in bigger D/G and 2D/G ratios. Polishing substrates just before deposition can decrease these ratios by as much as 15%. Here, the kind of carbon source has little effect on sample growth, with the exception of atmospheric development of graphene, which might not be an ideal condition due to energy lack of the carbon species. In-situ plasma plume analysis is carried out to evaluate the species being ablated in the target. Ablated species consist mainly of C+ ions, with a few neutral C and C2 species. Ablated C+ ions are in temperatures up to 12,000 K in vacuum and 10,000 K in .1 torr argon.

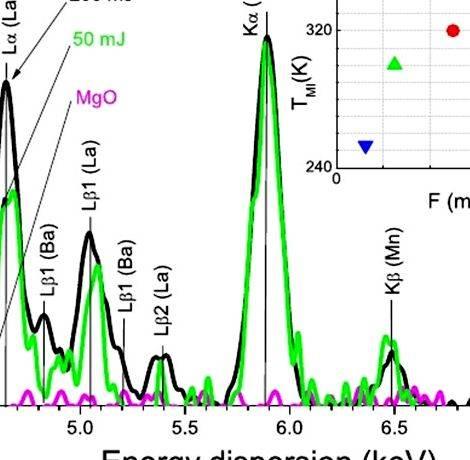

For bismuth telluride, optimal growth the weather is found for that stoichiometric change in Bi2Te3, which could change from system to system. Generally, a deposition temperature of 200°C along with a deposition pressure of .1-to-1. torr argon are needed for stoichiometric transfer. Utilizing a high energy laser for ablation results in smaller sized grain sizes within the nanostructured films. Additionally, utilizing a nitrogen atmosphere rather of argon results in elevated gas-phase condensation just before deposition, producing a highly featured surface. When outdoors from the ideal pressure range, the substrate material can considerably modify the surface morphology from the sample, varying from smooth films to nanoparticles and nanorods. These morphologies modify the electrical qualities from the material. Generally, the cheapest electrical resistance originated from films grown using 532 nm laser irradiation, which results in bigger grain sizes and much more featured surfaces. Films grown at slightly reduced pressure, which results in more featured surfaces, will also be lower in electrical resistance. These films also provide large Seebeck coefficients, each of which result in a greater thermoelectric figure of merit.

Committee: Dr. Stephen Tse (consultant), Dr. James Guo, Dr. Howon Lee and Dr. Bernard Kear

Storm warnings adrienne rich thesis proposal

Storm warnings adrienne rich thesis proposal University of central florida thesis proposal

University of central florida thesis proposal Organic rankine cycle phd thesis proposal

Organic rankine cycle phd thesis proposal Topics in psychology thesis proposal

Topics in psychology thesis proposal Kabataan noon at ngayon thesis proposal

Kabataan noon at ngayon thesis proposal