Significance and employ

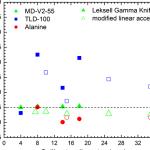

5.1  It is essential to acknowledge the results acquired with this test method or other way of particle size determination utilizing different physical concepts may disagree. The outcomes are strongly affected by physical concepts utilized by both ways of particle size analysis. The outcomes associated with a particle sizing method ought to be used only inside a relative sense and cannot be considered as absolute when evaluating results acquired by other methods. Designed for fine materials (that’s, average particle size 20 μm), significant variations are frequently observed for laser light scattering instruments of various manufacturers. These variations include lasers of various wavelengths, detector configuration, and also the algorithms accustomed to convert scattering to particle size distribution. Therefore, comparison of is a result of different instruments might be misleading. 3

5.2  Light scattering theories (Fraunhofer Diffraction 4 and Mie Scattering 5 ) that can be used for resolution of particle size happen to be available for several years. Several manufacturers of testing equipment are in possession of units according to these concepts. Although each kind of testing equipment utilizes exactly the same fundamental concepts for light scattering like a purpose of particle size, different assumptions pertinent to use of the idea and various models for converting light measurements to particle size, can lead to spun sentences for every instrument. In addition, any particles that are outdoors the dimensions measurement selection of the instrument is going to be overlooked, causing a rise in the reported percentages inside the detectable range. A particle size distribution which ends up abruptly in the recognition limit from the instrument may suggest that particles outdoors the number can be found.

Therefore, utilization of this test method cannot guarantee directly comparable is a result of various kinds of instruments.

5.3  This test method may be used to determine particle size distributions of catalysts, supports, and catalytic recycleables for specifications, manufacturing control, and development and research work.

5.4 ਏor fine materials (that’s, average particle size 20 μm), it is important that Mie Scattering Theory be used. This requires entering an “optical model” composed from the “real” and “imaginary” refractive indices from the solid in the wave length from the laser. The “imaginary” refractive index is also called the �sorbance,” as it features a worth of zero for transparent materials for example sand. For common materials not to mention occurring minerals (for instance, kaolin), these values are known and printed, in most cases incorporated within the manufacturer’s instrument manual (for instance, being an appendix). For instance, kaolinite measured at 589.3 nm includes a “real” refractive index of just one.55. The absorbance (imaginary component) for minerals and metal oxides is generally taken as .001, .01 or .1. Most of the printed values were measured at 589.3 nm (sodium light) but frequently values at other wavelengths will also be given.

Extrapolation, interpolation, or estimation towards the wave length from the laser getting used can therefore be produced. 6

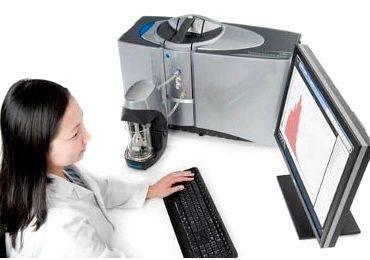

1.1  This test method covers the resolution of the particle size distribution of catalyst, catalyst carrier, and catalytic raw material particles and is among several found valuable for that measurement of particle size. The plethora of average particle sizes investigated was from 1 to 300 μm equivalent spherical diameter. The process is capable of doing calculating particles above and below this range. The position and concentration of laser light scattered through the particles are selectively measured allowing calculation of the volume distribution using light-scattering techniques.

1.2  The values mentioned in SI units should be considered as standard. Not one other units of measurement are incorporated within this standard.

1.3  This standard doesn’t purport to deal with all the safety concerns, or no, connected using its use. It’s the responsibility from the user of the standard to determine appropriate safe practices practices and see the applicability of regulatory limitations just before use.

D3766 Terminology Associated with Catalysts and Catalysis

E105 Practice for Probability Sampling of Materials

E177 Practice for Utilisation of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Associated with Quality and Statistics

E691 Practice for Performing an Interlaboratory Study to look for the Precision of the Test Method

E1617 Practice for Reporting Particle Size Portrayal Data

ICS Number Code 19.120 (Particle size analysis. Sieving)

The writing on my forehead by nafisa haji

The writing on my forehead by nafisa haji My favorite holiday writing prompts

My favorite holiday writing prompts Writing a dear customer letter

Writing a dear customer letter Describe your mother using adjectives in writing

Describe your mother using adjectives in writing Writing if then hypothesis worksheet kindergarten

Writing if then hypothesis worksheet kindergarten