Comprehending The Results Of DRYING METHODS ON WOOD MECHANICAL Qualities AT ULTRA AND CELLULAR LEVELS

Pierre Blanchet, Alizera Kaboorani Kaboorani, Cecilia Bustos

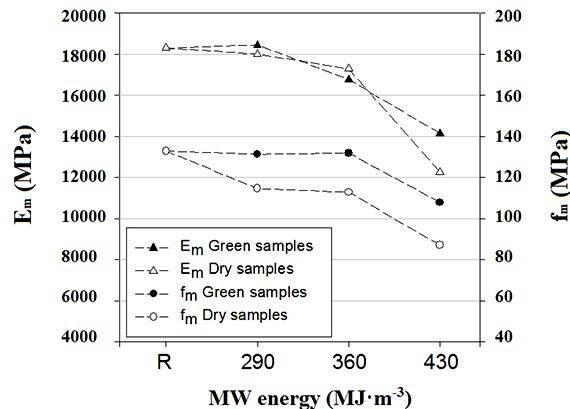

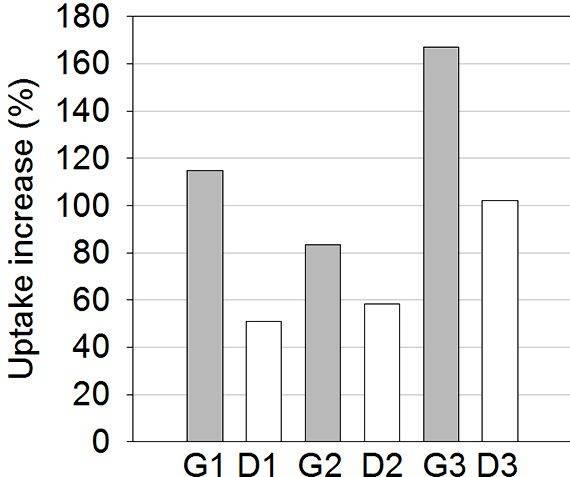

Conventional kiln and vacuum drying are generally utilized in industry to dry wood. Within this research, an effort is made to build up a much better knowledge of the results of both drying methods around the mechanical qualities of wood in the ultra-structure and cellular structure levels. Dynamic mechanical analysis (DMA) and nanoindentation (NI) were utilised along with standard static bending tests based on ASTM D143 to evaluate the particular results of both drying methods around the performance of yellow birch (Betula alleghaniensis Brit.) wood, an essential species within the Canadian wood industry. Measurements of equilibrium moisture content (EMC) at different relative humidity (RH) levels demonstrated that vacuum drying consistently produced greater EMC values. Vacuum-dried wood also exhibited superior MOE and MOR performance. Tests conducted by DMA shown the chemical structure of wood had gone through more changes during conventional kiln drying than during vacuum drying. The elastic modulus and hardness measured through the nanoindentation technique says the outcome of wood drying could be detected in the cell wall level too. The outcomes of the study demonstrated the perfect attention ought to be compensated towards the results of specific drying methods around the chemical structure of wood, because the chemical changes occurring within the kiln effect on the caliber of the ultimate products.

yellow birch wood, mechanical qualities, drying method, nanoindentation(NI), dynamic mechanical analysis (DMA), yellow birch

Avramidis S, Liu M, Neilson BJ(1994) Radio-frequency/vacuum drying of softwoods: drying of thick western red cedar plank with constant electrode current. Forest Prod. J. 44(1):41-47.

Backman AC, Lindberg KAH (2001) Improvement in wood material responses for radial and tangential direction as measured by dynamic mechanical thermal analysis. Journal of fabric Science 36 (15): 3777–3783.

Barefoot AC, Hitchings RG, Ellwood EL(1965) Wood characteristics of kraft paper qualities of 4 selected loblolly pines. III. Aftereffect of fiber morphology on pulp. Tappi 49:137–47.

Berry S, Roderick M(2005) Plant-water relations and also the fibre saturation point. New Phytologist 168:25–37.

Bowyer JL, Shmulsky R. Haygreen JG (2003) Forest Products and Wood Science Iowa Condition Press: Ames, IA, USA.

Cai Y, Hayashi K (2007) New monitoring idea of moisture content distribution in wood during RF/va¬cuum drying. Journal of Wood Science 53:1-4.

Cheng YT, Cheng CM (2004) Scaling, dimensional analysis, and indentation measurements,” Materials Science and Engineering Reports: R44: 91.

Curling, SF, Winandy JE, Clausen CA(2002) Experimental approach to evaluate progressive stages of decay of wood by basidiomycete fungi. Worldwide Biodeterioration and Biodegradation 49: 13-19.

Edvardsen K, Sandland KM (1999) Elevated drying temperature – Its affect on the dimensional stability of wood, European Journal of Wood and Wood Products 57(3):207-209.

Fengel D, Wegener G (1989) Wood: Chemistry, Ultrastructure, Reactions.

De Gruyter, Berlin.

Fisher-Cripps AC (2011) Nanoindentation. Springer, New You are able to, USA.

Hansson L, Antti AL (2006) The result of drying method and temperature level around the hardness of wood Journal of Materials Processing Tech. 171(3): 467-470.

He M J, Chen WX, Dong XX (2000) Macromolecular Physics. Fudan College Publishing House, Shanghai, China 224–228 (in Chinese).

Herjrvi H (2002) Qualities of birch (Betula pendula, B. pubescens) for sawmilling and additional processing in Finland. Finland, Finnish Forest Research Institute, Research papers 871. 52 p.

Hill CAS (2006) Wood Modification: Chemical, Thermal along with other Process. John Wiley and Sons Limited. Chichester.

Hill C (2014) Thermally Modified Wood – the function of hemicelluloses. Final Cost Action FP0904 Conference “Recent Advances in the area of TH and THM Wood Treatment” May 19-21, 2014, Skellefte, Norway.

Hillis SWE (1984) Hot temperature and chemical effects on wood stability. Wood Sci Technol 18:281-293.

Hinterstoisser B, Weingrtner J, Praznik W. (1992) Influence of wood drying processes around the carb matrix of wood of Picea Abies. In Proceedings of 3rd IUFRO Worldwide Wood Drying Conference, Vienna, Austria, August 18-21, 217-221.

Hirai N, Sobue N. Asano I(1972) Studies on piezoelectric aftereffect of wood IV. Aftereffect of heat treatment on cellulose crystallites and piezoelectric aftereffect of wood. Mokuzai Gakkaishi 18 (6): 535–542.

Gerhards CC, McMillan JM (1976) High-temperature drying effects on mechanical qualities of softwood lumber: Proceedings of the research conference 1976 Feb 25-26. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. Madison, WI, USA. 161 pp.

Gindl W, Gupta HS, Grunwald C (2002) Lignification of brighten tracheid secondary cell walls associated with longitudinal hardness and modulus of elasticity using nano-indentation. Can J Bot 80(10):1029-1033.

Gindl W, Gupta HS (2002) Cell-wall hardness and Young’s modulus of melamine-modified brighten wood by nano-indentation. Comp Medicare Part A 33(8):1141-1145.

Gindl W, Gupta HS, Schberl T, Lichtenegger HC, Fratzl P (2004) Mechanical qualities of brighten wood cell walls by nanoindentation. Appl Phys A 79:2069-2073.

Gu H, Youthful TM, Moschler WW, Bond BH (2004) Potential causes of variation that influence the ultimate moisture content of kiln- dried hardwood lumber. Forest Prod. J. 54(11):65-70.

Imamura Y (1993) Estimation from the yeast resistance of wood composites for structural use. Current Japanese Materials Research 11: 75-84.

Isomki O, Koponen H, Nummela A, Suomi-Lindberg L(2002) Puutuoteteollisuus 2. Raaka-aineet ja aihiot. [Wood products industries 2. Recycleables and semi-finished products]. Edita Oy, Helsinki. 154 p. (In Finnish).

Jalava M (1945) Strength qualities of Finnish pine, brighten, birch and aspen. Communicationes Instituti Forestalis Fenniae 33(3): 1-66. In Finnish with British summary.

Jiang JL, Lu JX (2006) Moisture dependence from the dynamic viscoelastic qualities for wood. Journal of Beijing Forestry College 28 (Suppl. 2), Beijing, China, 118–123.

Jiang JL, Lu JX (2008) Dynamic Viscoelasticity of Wood After Various Drying Processes, Drying Technology: An Worldwide Journal 26(5): 537-54.

Jiang JL, Lu JX (2009) Dynamic viscoelastic behavior of wood under drying conditions. Front. For. China 4(3): 374–379.

Jiang J, Lu J and Yan H (2008). Dynamic viscoelastic qualities of wood treated by three drying methods measured at high-temperature range. Wood Fiber Sci. 40(1): 72-79.

Kanagawa Y, Hayashi K, Yasujima M (1993) Change of dry ability under vacuum drying by improvement of permeability of wood. Vacuum Drying of Wood’ 93. High Tatras, Slovakia. 292 pp.

Kelley SS, Rials TG, Glasser WG(1987) Relaxation conduct from the amorphous aspects of wood. J. Mater. Sci. 22: 617-624.

Kim G, Jee W, Ra J (1996) Decrease in mechanical qualities of Radiata pine connected with incipient brown-rot decay. Mokchae Konghak 24 (1): 81-86.

Konnerth J, Eiser M, Jger A, Bader TK, Hofstetter K, Follrich J, Ters T, Hansmann C, Wimmer R (2010) Macro- and micro-mechanical qualities of red oak wood (Quercus rubra L.) given hemicellulases. Holzforschung, 64 (4): 447-453.

LeVan SL, Ross RJ, Winandy JE (1990) Results of fire-proof chemicals on bending qualities of wood at elevated temperatures. Res. Pap. FPL-RP-498

Mano F(2002) The viscoelastic qualities of cork. Journal of fabric Science 37 (2): 257–263.

Mitchell PH, Barnes HM (1986) Aftereffect of drying temperature around the obvious wood strength of southern pine given CCA-type A. Forest Prod. J. 36(3):8-12.

Mitchell RL, Seborg RM. Millet MA (1953) Aftereffect of heat around the qualities and chemical composition of Douglas-fir wood and it is major components. Journal of Forest Product Research Society 3:38-42.

Mttnen V(2005) Variation of colour and selected physical and mechanical qualities associated with artificial drying of sawn silver birch (Betula pendula Roth) timber from plan-tations. Doctorate thesis, Dissertationes Forestales, 43 pp.

Oliver WC, Pharr GM (1992) A better way of figuring out hardness and elasticmodulus using load and displacement sensing indentation experiments. J Mater Res 7(6):1564-1583.

Oloyede A, Groombride P (2000) The influence of microwave heating around the mechanical qualities of wood. J. Mater. Process. Technol. 100: 67-73.

Cost EW, Koch P (1980) Kiln some time and temperature affect shrinkage, warp and mechanical qualities of Southern Pine lumber. Forest Prod. J. 30(8): 41-47.

Ressel J B (1999) Condition from the art for vacuum drying within the woodworking industry. Cost Action E15, 13-14 October 1999, Edinburgh, United kingdom.

Schmidt EL, French DW, Gertjejansen R, Herman J, Hall H (1978) Strength reductions in particleboard brought on by fungi. Forest Prod. J. 28 (2): 26-31.

Sehlstedt-Persson M (2000) The result of drying temperature on subsequent moisture and dimensional change for Scots pine and Norwegian brighten. Holz als Roh- und Werkstoff 58(5):353.

Sik H. Choo K, Zakaria S, Ahmad S, Yusoff M, Chia C(2010) The Influence of drying temperature around the hygroscopicity of rubberwood (Hevea Brasiliensis). Journal of Farming Science. 2(1): 48-58.

Sjestrm, E (1981) Wood Chemistry Fundamentals and Applications. Academic Press, New You are able to.

Suchy M, Virtanen J, Kontturi E. Vuorinen T (2010) Impact of Drying on Wood Ultrastructure Observed by Deuterium Exchange and Photoacoustic Foot-IR Spectroscopy. Biomacromolecules 11: 2161–2168.

Sugiyama M. Norimoto M (1996) Temperature dependence of dynamic viscoelasticities of chemically treated wood. Mokuzai Gakkaishi 42 (11):1049–1056.

Sugiyama M, Norimoto M(2006) Dielectric relaxation water adsorbed on chemically treated examples. Holzforschung 60 (5): 549–557.

Sweet M, Winandy JE (1999) Influence of amount of polymerisation of cellulose and hemicellulose on strength reduction in fire-retardant-treated southern pine. Holzforschung 53 (3): 311- 317.

Takamura A (1968) Studies on hot pressing and drying process in producing fibreboard. III. Softening of fibre components in hot pressing of fibre pad. Mokuzai Gakkaishi, 14: 75–79.

Thiam M, Milota MR, Leichti R(2002) Aftereffect of high-temperature drying on bending and shear strengths of western hemlock lumber. Forest Prod. J. 52(4): 64-68.

Tze WTY, Wang S, Rials TG, Pharr GM, and Kelley SS (2007) Nanoindentation of wood cell walls: Continuous stiffness and hardness measurements.Compos Medicare Part A: Appl S 38: 945–953.

Wagenfhr R(1996). Holzatlas. [Wood Atlas]. VEB Fachbuchverlag Leipzig. fourth erectile dysfunction. 688 p. (The German Language).

Welling J (1994) Superheated steam vacuum drying of timber-selection of application and advantages. fourth IUFRO Worldwide Wood Drying Conference, Rotorua, Nz: 460-461.

Whistler RL, Chen CC (1991) Hemicelluloses. In: Lewin, Goldstein (eds) Wood structure and composition. Worldwide fiber science series. Vol. 11. Marcel Decker. Imc. New You are able to, NY, USA, 287-320 pp.

Wilcox WW (1978) Overview of literature around the results of initial phases of decay on wood strength. Wood and Fiber 9 (4): 252-257.

Wimmer R, Lucas BN, Tsui TY, Oliver WC (1997) Longitudinal hardness and Young’s modulus of brighten tracheid secondary walls using nanoindentation technique. Wood Sci Technol 31(2): 31-141.

Winandy, JE, Morrell JJ (1993) Relationship between incipient decay, strength, and chemical composition of Douglas-Fir heartwood. Wood Fiber Sci 25 (3): 278-288.

Winandy, JE (1995) Results of fire-proof treatments after 18 several weeks of exposure at 150°F (66°C). Res. Note FPL-RN-0264. USDA Forest Serv. Forest Prod. Lab. Madison, WI.UAS.

Winandy JE, Lebow P (2001) Modeling strength reduction in wood by chemical composition. Part I. a person component model for southern pine. Wood Fiber Sci. 33(2): 239-254.

Zhan JF, GU JY, Shi SQ (2009) Rheological Behavior of Larch Timber during Conventional Drying, Drying Technology: An Worldwide Journal, 27(10): 1041-1050.

Zhang B. Liu D (2006) Exploring a brand new developing method of wood drying technology in China. China Forest Prod Ind 33(4): 3-6.

Refbacks

- You will find presently no refbacks.

Phenomenology architecture thesis proposal titles

Phenomenology architecture thesis proposal titles What is hypothesis in research proposal

What is hypothesis in research proposal Hypothesis of research proposal pdf

Hypothesis of research proposal pdf Phd dissertation powerpoint proposal presentation

Phd dissertation powerpoint proposal presentation Introduire une conclusion dans une dissertation proposal

Introduire une conclusion dans une dissertation proposal