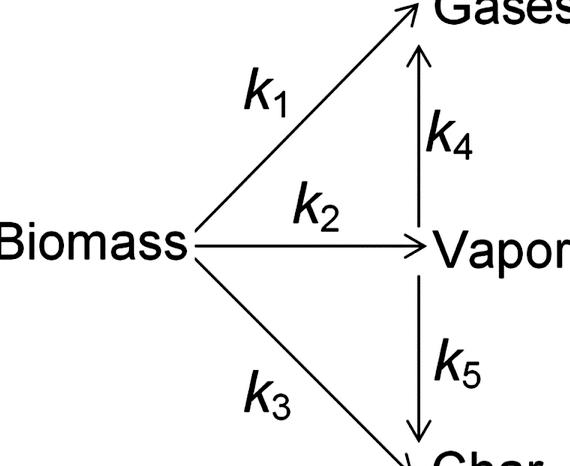

Summary of Thermochemical Processes

The figure below represents the fundamental idea of our regions of research around the thermochamical conversion of bio-waste into second generation fuels, chemicals and biochar.

An immediate liquefaction process leads to producing a bio-oil in the condensable volatile aspects of biomass. Typically, conditions of pyrolysis are utilized to have this. Pyrolysis can be viewed as is the thermal management of a fabric even without the oxygen that may also result in the evolution of non-condensable gases along with a residual solid component that doesn’t decompose underneath the conditions employed (a biochar ). With time, refinements have permitted process conditions and also the feedstock to become manipulated to have high yields of bio-oil. gases, or biochar. with respect to the particular end result preferred.

Under flash (or fast) pyrolysis. the feedstock is ground to very fine particles, to be able to facilitate rapid heat transfer, and moderate temperatures of 450-700oC are utilized for any very short residences time (within the order of seconds). The gases evolved are quickly quenched to avoid their depolymerisation to non-condensable gases. The finish outcome is a higher yield of bio-oil. which can be as much as 70% by mass from the feedstock, with respect to the beginning material.

This bio-oil is really a complex combination of water, carboxylic acids and lignin- and carb-derived items that can deteriorate quickly with time, with polymerisation reactions developing additional water and causing phase separations. Dynamotive. a business which has commercial facilities producing electricity through the combustion of bio-oil, declare that the bio-oil created from sugarcane baggasse processed within their flash pyrolysis reactor contained a range of products [135] including water (20.8%), levoglucosan (3.%), hydroxyacetaldehyde (10.2%), acetic acidity (6.6%), and chemicals (3.4%).

Ensyn is yet another company with several commercial-scale bio-oil to energy facilities.

Because of the existence of water and abundance of oxygen, the heating worth of the biooil is low when compared with fossil oils and it is only appropriate like a heating fuel. You can use it like a beginning point to a transport fuel if catalytic upgrading mechanisms are utilized. Alternatively, there might (based on the chemical composition from the beginning feedstock) be valuable chemicals that may be obtained from the bio-oil.

Ultimately, it’s wished that, through either catalytic upgrading after pyrolysis or through modifications towards the pyrolysis process itself, an oil could be created that’s appropriate like a transport fuel or works with existing petrochemical processing facilities. A manufacture of a bio-oil that’s a viable substrate for biochemical processing is yet another option. This will happen via acidity hydrolysis from the levoglucosan to glucose, but there also microorganisms that may directly ferment levoglucosan.

Where lower temperatures (300-550oC) are utilized and also the biomass is less finely comminuted, residence occasions are usually longer (slow pyrolysis ) along with a greater yield of biochar results at the fee for significant bio-oil formation. These temperatures facilitate the depolymerisation of polysaccharides with their slow lack of fluids to unsaturated species that may further react, via a range of potential pathways, to unsaturated polymers and char.

The biochar that’s created is of worth, both like a fuel because of its high energy content (

30 GJ/t [117]) so that as a soil amender because of the porosity qualities conferred by particular pore-sizes, and also the ultrastructure that derive from the pyrolysis process. For additional info on bochar please make reference to the right website on Carbolea.

As opposed to slow pyrolysis, the greater temperatures of fast pyrolysis increase the risk for depolymerised polysaccharides being made volatile and developing complex tars and oils. Once the the weather is so severe (over 700oC) these tars are extensively damaged to non-condensable gases, a possible fuel gas, that contains hydrogen and methane in addition to carbon oxides, is created. Just like gasification technologies, this gas has potential like a feedstock for chemical synthesis via various catalytic pathways.

An in depth thought on the feedstock of great interest can also be frequently necessary when predicting the way it will work under pyrolysis, and just what finish products will result. For instance, ash has a tendency to promote char formation during pyrolysis and also the bio-oils which are produced by high-ash feedstocks could have high amounts of swimming pool water and alkali metals for example potassium which may be damaging to turbines when the oil will be utilised for power production.

At Carbolea we’ll shortly receive a stainless-steel reactor (1.5 dm3), designed and created to our specifications and highlighted below, to conduct pyrolysis of biomass in moderate pressure (as much as 30 atm). Bio-oil inside a vapour form is going to be transported towards the catalytic reactor and cracking experiments is going to be performed. Characterisation of product bio-oil includes CHNOS elemental analysis, H2O by Karl Fisher, Calorific vale, Acidity, ester, iodine value, density, viscosity, pH, etc. We’ll also shortly possess a bigger gasification system that may also run within the pyrolysis mode. For additional info on this apparatus please consult the right website.

Hayes, D. J. M.  (2013) Second-generation biofuels: why they’re taking such a long time, Wiley Interdisciplinary Reviews: Energy and Atmosphere  2(3):304334

Click for abstract

There’s been a substantial amount of hype concerning the commercial potential of second?generation biofuels (2GBs biofuels sourced from lignocellulosic materials). In 2007, ambitious targets for that mass substitution of fossil?fuel?derived transport fuels by 2GBs were submit within the U . s . States and other alike targets exists for other countries. However, by May 2012, no commercial?scale 2GB facilities are presently operating. The technical and financial obstacles which have delayed the deployment of those facilities are discussed, much like recent advancements in research that might help to beat a few of these. You will find six commercial?scale facilities presently (May, 2012) in construction and much more are planned soon. The prospects for 2GBs tend to be more promising now than previously however the delays to get up to now imply that the ambitious targets of in the past are unlikely to become arrived at soon.

Troy S.M.. Nolan T. Leahy J.J.. Lawlor P.G. Healy M.G. Kwapinski W.  (2013) Effect of sawdust addition and composting of feedstock on alternative energy and biochar production from pyrolysis of anaerobically digested pig manure, Biomass and Bioenergy

F. Melligan. M.H.B. Hayes. W. Kwapinski. J.J. Leahy  (2013) A study of hydrogen pressure during hydropyrolysis of Miscanthus x giganteus an internet-based catalytic vapour upgrading with Ni on ZSM-5, Journal of Analytical and Applied Pyrolysis

Click for abstract

Hydropyrolysis, along with another catalytic reactor was utilized as a technique of manufacturing a bio-oil from Miscanthus x giganteus with lower levels of oxygenated compounds and yields of saturated hydrocarbons. This research used analytical Pyrolysis-gas chromatography/mass spectroscopy for that analysis of merchandise in the pyrolysis of Miscanthus. Hydropyrolysis was transported out at 600 C, and also the pyrolysis vapours then undergone another reactor, which contained a tenPercent Ni on ZSM-5 catalyst. The hydrogen pressure for that separate reactions ranged from atmospheric pressure as much as 30 bar. The outcomes indicate that both hydrogen pressure and also the incorporation from the Ni/ZSM-5 catalysts play a huge role in producing saturated hydrocarbons with the hydrogenation, lack of fluids and decarboxylation of oxygenated compounds. Also, even without the the catalyst the power of ethanoic acidity could be considerably reduced with the rise in hydrogen pressure, and completely eliminated at 20 bar.

Melligan, F.. Dussan, K.. Auccaise, R. Novotny, E. H. Leahy, J. J.. Hayes, M. H. B.. Kwapinski, W.  (2012) Characterisation from the products from pyrolysis of residues after acidity hydrolysis of Miscanthus , Bioresource Technology  108:258-263

Click for abstract

Platform chemicals for example furfural and hydroxymethylfurfural are major products created throughout the acidity hydrolysis of lignocellulosic biomass in second generation biorefining processes. Solid hydrolysis residues (HR) can add up to 50 wt.% from the beginning biomass materials. Pyrolysis from the HRs brings about biochar, bio-fluids, and gases. Some time and temperature were variables throughout the pyrolysis of HRs inside a fixed bed tubular reactor, and both parameters have major influences around the amounts and qualities from the products. Biochar, with possibility of carbon sequestration and soil conditioning, composed about 50 % from the HR pyrolysis product. The amounts (1120 wt.%) and compositions (as much as 77% of phenols in organic fraction) from the bio-fluids created claim that these haven’t much value as fuels, but tend to be causes of phenols, and also the gas might have application like a fuel.

Girisuta B.. Kalogiannis, K. G. Dussan, K.. Leahy, J. J.. Hayes, M. H. B.. Stefanidis, S. (2012) An integrated process for producing platform chemicals and diesel miscible fuels by acidity-catalyzed hydrolysis and downstream upgrading from the acidity hydrolysis residues with thermal and catalytic pyrolysis, Bioresource Technology  126:92-100

Li Z.. Wnetrzak R.. Kwapinski W.. Leahy J.J.  (2012) Synthesis and characterisation of sulfated TiO2 nanorods and ZrO2/TiO2 nanorod composites for that esterification of bio-oil model organic acidity, ACS Applied Materials & Interfaces  4:4499-4505

Melligan, Fergus. Karla Dussan. Ruben Auccaise, Etelvino H Novotny, James J Leahy. Michael H.B. Hayes. Witold Kwapinski  (2012) Characterisation from the products from pyrolysis of residues after acidity hydrolysis of Miscanthus, Bioresource Technology  108:258-263

Click for abstract

Platform chemicals for example furfural and hydroxymethylfurfural are major products created throughout the acidity hydrolysis of lignocellulosic biomass in second generation biorefining processes. Solid hydrolysis residues (HR) can add up to 50 wt.% from the beginning biomass materials. Pyrolysis from the HRs brings about biochar, bio-fluids, and gases. Some time and temperature were variables throughout the pyrolysis of HRs inside a fixed bed tubular reactor, and both parameters have major influences around the amounts and qualities from the products. Biochar, with possibility of carbon sequestration and soil conditioning, composed about 50 % from the HR pyrolysis product. The amounts (11-20 wt.%) and compositions (as much as 77% of phenols in organic fraction) from the bio-fluids created claim that these haven’t much value as fuels, but tend to be causes of phenols, and also the gas might have application like a fuel.

Melligan, F.. J.J. Leahy. W. Kwapinski. M.H.B. Hayes  (2012) Hydro-pyrolysis of biomass as well as on-line catalytic vapour upgrading with Ni-ZSM and Ni-MCM-41, Energy and Fuels  26:6080-6090

Click for abstract

A catalyst reactor along with analytical pyrolysis gas chromatography/mass spectroscopy (Py-GC/MS) was utilized to handle online research into the product vapors in the fast pyrolysis of Miscanthus x giganteus, Scots pine, and mahogany. Pyrolysis was transported in both an inert atmosphere of He gas as well as in a very reducing atmosphere of H2. Significant alterations in the vapor compositions were achieved by using H2 because the carrier gas. The most known of those were the increases within the hydrocarbon compositions. The roles of ZSM-5, Ni/ZSM-5, MCM-41, as well as Ni/MCM-41 catalysts around the compositions from the pyrolysis vapors were investigated. Lower levels of the greater molecular weight phenolic compounds and bigger levels of the lighter phenols were noticed in the existence of Ni supported on ZSM-5 and MCM-41. This effect was more apparent for that 10% compared to the two.5% Ni loadings. Overall, the outcomes both from using H2 because the carrier gas and all the catalysts demonstrates significant enhancements within the composition from the vapors. However, this led to the cut in the amount of condensable products.

Novotny E.H. Auccaise R. Velloso M.H.R. Corra J.C. Higarashi M.M. Abreu V.M.N. Rocha J.D. Kwapinski W.  (2012) Characterization of phosphate structures in biochar from swine bones, Pesquisa Agropecuria Brasileira  47:672-676

Click for abstract

The goal of the work ended up being to develop an alternate methodology to review and characterize the phosphate crystalline qualities, directly connected with solubility and plant availability, in biochar from swine bones. Some phosphate symmetry qualities of pyrolyzed swine bones were established, using solid condition nuclear magnetic resonance spectroscopy, principal component analysis, and multivariate curve resolution analysis, on four pyrolyzed samples at different carbonization intensities. Growing carbonization parameters (temperature or residence time) generates diverse phosphate structures, growing their symmetry and reducing the entered polarizability from the pair 1H-31P, producing phosphates with, most likely, lower solubility compared to ones created at lower carbonization intensity. Furthermore, a brand new methodology has been designed to study and characterize phosphate crystalline qualities directly connected with phosphate solubility and availability to plants.

Bulushev,D.A.. Ross,J.R.H.  (2011) Catalysis for conversion of biomass to fuels via pyrolysis and gasification: an evaluation, Catalysis Today  171(1):113

Click for abstract

A present purpose of society would be to produce fuels from non-food biomass and catalysis is central to accomplishing this aim. Catalytic steam-reforming of biomass gives synthesis gas which is further transformed to provide transport fuels using catalysis. Biofuels and fuel additives may also be acquired by catalytic upgrading of bio-oil created by non-catalytic pyrolysis of biomass. This upgrading can be carried out by cold esterification with alcohols (adopted by water separation) or by hot temperature gasification, cracking or hydrotreating processes. Upgraded bio-oil may also be acquired by pyrolysis of biomass in the existence of catalysts. This review views recent trends within the chemistry of those systems for biofuel production and also the catalysts used.

Melligan, F.. Auccaise, R. Novotny, E. H. Leahy, J. J.. Hayes, M. H. B.  (2011) Pressurised pyrolysis of Miscanthus utilizing a fixed bed reactor, Bioresource Technology  102(3):34663470

Click for abstract

Miscanthus x giganteus was pyrolysed, inside a fixed bed reactor inside a constant flow of dinitrogen gas, for a price of 13 C/min from ambient to 550 C, then held for twenty five min only at that temperature. The pressures employed ranged from atmospheric to 26 bar. The main compounds identified within the bio-oil were water, phenol, and phenol derivatives. Water contents effect on the effectiveness from the bio-oil like a fuel. However, the phenols could provide helpful platform chemicals and merchandise. The qualities from the char were determined using elemental analyses, area measurements while using BrunauerEmmettTeller equation, a calorimetric explosive device, Checking Electron Microscopy, and solid condition 13C NMR spectroscopy. The chars were highly carbonised, especially in the greater pressures, and provided thermally stable materials. Pressure impacted greatly at first glance area. Char created at atmospheric pressure were built with a area of 162 m2/g, whereas that in the greatest pressure applied was just .137 m2/g

Melligan F.. Leahy J. J.. Hayes M.H.B.. Kwapinski W.  (2012) Hydro-pyrolysis of biomass as well as on-line catalytic vapour upgrading with Ni-ZSM-5 and Ni-MCM-41, COST UBIOCHEM, 3rd Workshop, Thessaloniki A holiday in greece, 1-3 November :17

Fox A. Cullen R. Kwapinski, W.. Schmalenberger A. (2012) Bacterial mobilization of sulfur and phosphorous in biochar amended soils, 14th Worldwide Symposium on Microbial Ecosystem The strength of the little , Copenhagen, Denmark, 19-24 August 2012

M.H.B. Hayes. C.M.P. Byrne  (2012) Characterization of Biochar from Pyrolysis of Miscanthus x giganteus, Its Impact on Plant Growth and it is Possibility of Carbon Sequestration, Eurosoil Conference , Bari, Italia, This summer 2-6

Melligan F.. Leahy J.J.. Hayes M.H.B.. Kwapinski W.  (2012) PyGC/MS of Miscanthus with Ni-ZSM-5 and Ni-MCM-41 within hydrogen atmosphere, 19th Worldwide Symposium on Analytical and Applied Pyrolysis , Linz, Austria, 21-25 May

Wnetrzak R.. Leahy J.J.. Peters K. Jensen L.S. Kwapinski W.  (2012) Energy production potentials from pyrolysis of pig manure, fourth Worldwide Symposium on Energy from Biomass and Waste , San Servolo, Venice, Italia, November. 12-15

Hayes, D. J. M.  (2010) Pyrolysis and also the Production and Utilisation of Biochar, Environmental protection agency Waste to Resource Conference , Dublin, Ireland, Sep. 27th 2010

Download

Melligan, F.  (2009) Pyrolysis of Biomass to create Bio-Oil, IRCSET 2009 Symposium – Innovation Fuelling the Smart Society , Dublin, 25 Sep 2009

Download

Kwapinski, W.  (2009) Biomass Pyrolysis and Gasification as well as their Applications, IRCSET 2009 Symposium – Innovation Fuelling the Smart Society , Dublin, 25 Sep 2009

Download

Kwapinski W.. Leahy J.J.  (2012) Feasibility study for the making of an airplane pilotOrindustrial – scale pyrolysis unit, Report for that Reason for Financial aspects of Sustainability (FEASTA) :38 pages

Carbolea member Fergus Melligan today passed his PhD viva. His thesis is titled Pyrolysis of Biomass and Biorefinery Residual Materials for producing Advanced Biofuels. He’s tried the DIBANET project producing and characterising biochar and bio-oil in the acidity hydrolysis residues. He’s also transported out pot-trials to look for the effects that adding this biochar to soil might have on plant growth.

Paper Printed on Pyrolysis of Residues in the DIBANET Process

A paper continues to be printed that contains work by Carbolea people around the pyrolysis from the acidity hydrolysis residues which are created like a consequence from the DIBANET process. The paper is titled Characterisation from the products from pyrolysis of residues after acidity hydrolysis of Miscanthus and could be downloaded from ScienceDirect .

Abstract: Platform chemicals for example furfural and hydroxymethylfurfural are major products created throughout the acidity hydrolysis of lignocellulosic biomass in second generation biorefining processes. Solid hydrolysis residues (HR) can add up to 50 wt.% from the beginning biomass materials. Pyrolysis from the HRs brings about biochar, bio-fluids, and gases. Some time and temperature were variables throughout the pyrolysis of HRs inside a fixed bed tubular reactor, and both parameters have major influences around the amounts and qualities from the products. Biochar, with possibility of carbon sequestration and soil conditioning, composed about 50 % from the HR pyrolysis product. The amounts (1120 wt.%) and compositions (as much as 77% of phenols in organic fraction) from the bio-fluids created claim that these haven’t much value as fuels, but tend to be causes of phenols, and also the gas might have application like a fuel.

Melligan, F. Dussan, K.. Auccaise, R. Novotny, E. H. Leahy, J. J.. Hayes, M. H. B.. Kwapinski, W. (2012) Characterisation from the products from pyrolysis of residues after acidity hydrolysis of Miscanthus,Bioresource Technology. 108, 258-263

Civil engineering topics for thesis proposal

Civil engineering topics for thesis proposal English literature thesis proposal sample

English literature thesis proposal sample Case study thesis title proposal on education

Case study thesis title proposal on education Masters thesis proposal presentation ppt overview

Masters thesis proposal presentation ppt overview Mit architecture master thesis proposal

Mit architecture master thesis proposal